Building Generic Canneries (II)

Generic Canneries is a mixed concrete brick building. Both concrete and brick are challenging effects to create on a plastic model.

Although I think "grey" when I visualize concrete, the reality is that concrete ages and fades into greyish-cream, almost pale yellow colour.

Above is a picture of the American Canning Company in Simcoe, Ontario before it was torn down. This is a rather gorgeous example of industrial architecture. You can see more of the building at https://www.uer.ca/locations/show.asp?locid=20330. Another picture is below.

Brick is also difficult to create. Most brick model kits have a reddish-brown colour with the brick being too shiny and no mortar lines. Painting a brick colour obviously gets rid of the shininess but the mortar problem remains. I tried many experiments to get the mix right. Brick colour as a base with a wash of white to capture the mortar. Or the reverse - white mortar first with a wash of brick colour over top. Later on I bought a special mortar paste which I used on Aston Growers.

In the end, I went with white mortar paint first with a reddish powder dusted on top allowing some of the white to show through. I weathered the concrete with grimy grey powder.

Overall, I like the effect although I would have preferred a less grimy concrete and more of a mortar effect. The brick colour pops as opposed to being subdued, but I prefer it that way.

The Roof

The roof was in two pieces. First, there was the plastic roof section where the water tower goes. Second, there was the larger roof area to cover the hexagonish main section. For that I used foam core board, regretting the choice later when it warped. I added roof granules (grey ballast) to both sections and some junk. Junk is helpful for hiding the gaps between the roof and the structure. I also added some vents and a heating unit.

I've mentioned this project was a challenge. The irregular building. The detail parts. Painting concrete and brick. Even the water tower was a pain - the two-piece kit refused to come together evenly but luckily I could hide the imperfections at the back. As the model came together, small parts of the wall came untogether and there are some imperfect joints where the walls come together. Attempting to close those gaps created gaps elsewhere so I left well enough alone.

The Shed

But the second part of the model was just as much of a challenge - the unloading shed.

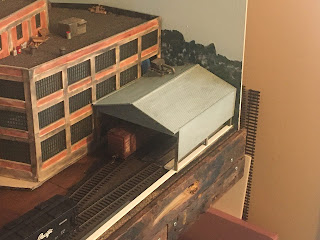

The concept behind the unloading shed is to provide a reason for the two spur tracks (in the right of the above photo). One spur is for powdered commodities and the second I thought would be for liquids and inbound boxcars.

|

| Nearly done! |

I built the shed from scratch using Evergreen plastic siding material. I suppose the shed is supposed to be made from sheet metal. I painted the shed a light grey with some weathering and rust patches. The grey is a little to "blue" and the siding too perfect, but I rationalized that this was a fairly new structure that had not lived for long in the elements.

One side of the shed is supported by the building with the other side resting on L-beams. One of the two spurs has a (simulated) concrete pad to prevent sugar, starch, liquids, etc. from soaking into the ballast and creating a mess. On top of the shed is a blower fan and two pipes to simulate the "suck and blow" process of unloading stuff from covered hoppers. The pad also gave me an excuse to add some additional styrene to level out the aisle side of the shed.

In the above photo, I have closed off the open window (at the back) and added piping into the building. You can also see the weathering.

When I was happy with the fit of the shed, I installed the building - finally adding the main spur track into the building, ballasting it and adding scenery at the back of the building. That scenery was some fencing and bushes and I was pleased with how it matches with the backdrop (although it is largely a sight unseen).

I also added a road between the two foreground spurs and the building using a plastic road I had bought as part of the bridge project. I weathered some tire tracks on the road.

The whole idea here is that the front of the building is unseen - rail spurs go into the back of a building. The front of the building - where the offices are, the main parking lot and a nicely landscaped garden, is unseen. But you need a way to get from the front to the back - hence the road which runs between the building and the shed.

Only then did I install the shed - about 6 months after I started the project!

Conclusion:

The miraculous about Generic Canneries is how I managed to make everything fit together. The shed isn't perfectly level. The track into the building is a little zig-zaggy. The roof sags and the corners aren't perfect. But as things go, I'd rate the final product as Excellent. The building, with its shed, clearly rates rail service.

There is still work to be done. I need to add a sign somewhere. The roof needs some lazy workers drinking out of sight of the shop foreman. The inside of the building needs a loading dock - perhaps. And finally, and most fun of all, there is the unfinished space between the two spurs. I envision some old truck trailers, a small shack and lots of weeds and junk. In my dreams, I can picture a few trailers in the GC fleet resting in anticipation of their next load.

Err, and also I need to figure out the actual name for Generic Canneries (or is it Canning?).

No comments:

Post a Comment