Building Generic Canneries (I)

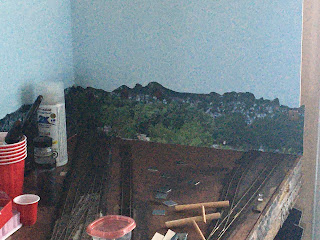

Returning to our scenery story, once the station area was (mostly) finished, I was left with this:

Empty space (yes, beneath the clutter).

I had an idea of what I wanted to do with the space but turning that into reality would take the better part of 2020. Yes, nearly 7 months to fill in about 3 square feet. This post begins that story.

What comes first?

The basic idea was this: Brick building in the front (Generic Canneries), concrete cold storage building (Aston Growers) in the back, overhead walkway/bridge to join the two. I added an unloading shed to the brick building (Generic canneries).

Generic Canneries came first because there was a kit I could use.

The George Roberts Printing Plant has to be a favourite of model railroaders for kitbashing. The building looks familiar but has enough character (and heft) to sit on a layout looking like it belongs there. As I've mentioned before, for me model railroading is about re-creating the everyday/commonplace of life but making it picturesque. A common problem on layouts is that a building is too small to justify the level of rail service it gets. The building should dwarf the freight cars, not vice versa.

The problem with George Roberts is that it is a rectangular building and I needed a sort of trapezoid. The good news for me is that part of the building was going against my backdrop so that side of the building could just be a blank or filler wall with no detail.

|

| June 15, 2020 |

The above photo shows the early stages. I used foamboard as a base. A not good idea, as it turned out because foam board warps if it gets wet (spray paint not being helpful either).

At this point, there is no backwall and sidewall had yet to be added.

Testing, Testing

|

| Test fitting #723 |

As I built the structure, I also had to keep in mind various dimensional considerations:

1. Leaving enough space between the building and to aisle facing sidings for the storage shed and a small road.

2. Angling the building so the spur track that goes into the building would not curve unnaturally.

3. Making sure the blank wall was flush to the backdrop.

4. ...and making sure the building did not interfere with the main line.

But the reward would be a building that would be hefty enough to justify the sidings attached to it.

The bespoke footprint of the building meant that I needed to create a roof to fit the structure. Again, I used foamboard because it was easy to cut it to fit. Five months later, having grown used to styrene, I wished otherwise (styrene doesn't warp).

A boring but necessary part of building Generic Canneries was adding interior bracing and view blocks. The interior bracing was needed to keep the roof in place and the walls straight. The view blocks prevent you from looking in one window and seeing through to the other side. In other words, something must be in the building.

Paint

The truth of the matter is that Generic Canneries was slow build. The kit was of medium difficulty to build. It had a lot of bits that needed to be painted before being placed (the exterior staircases being the best example). The structure itself was part concrete/part brick which further complicated painting (I wasn't going to paint it a uniform grey). I had a blank wall and room to custom fit. At the same time, the structure was finished enough that it could sit there - there was nothing time sensitive about it.

But I finally got to painting. I went with a beige base figuring it could pass for concrete when weathered. The brick portions were hand painted. I tried red brick then white (mortar). I tried white (mortar) then red brick. I tried white mortar then red brick (burnt sienna) weathering powder. Brick is tricky to model - a) you have to get the brick colour right and b) you have to hint at white mortar without disturbing the brick colour. Rather tricky.

|

| September 2020. |

In Part II, I'll cover more painting, talk about the excitement of roof granules and discuss detailing. Stay tuned!